All About A LED PCB Manufacturer You Must Know

Keywords: LED PCB Manufacturer

In today's fast-paced world, where technology continues to evolve at an astonishing rate, light-emitting diodes (LEDs) have emerged as a shining example of innovation. LED technology has revolutionized the lighting industry, offering energy-efficient, long-lasting, and versatile illumination solutions. Behind the scenes, the unsung heroes responsible for the success of LED technology are LED PCB Manufacturer. In this blog, we'll delve into the world of LED PCB manufacturers, exploring their importance, key considerations when choosing one, and the role they play in the LED lighting industry.

The Significance of LED PCB Manufacturers

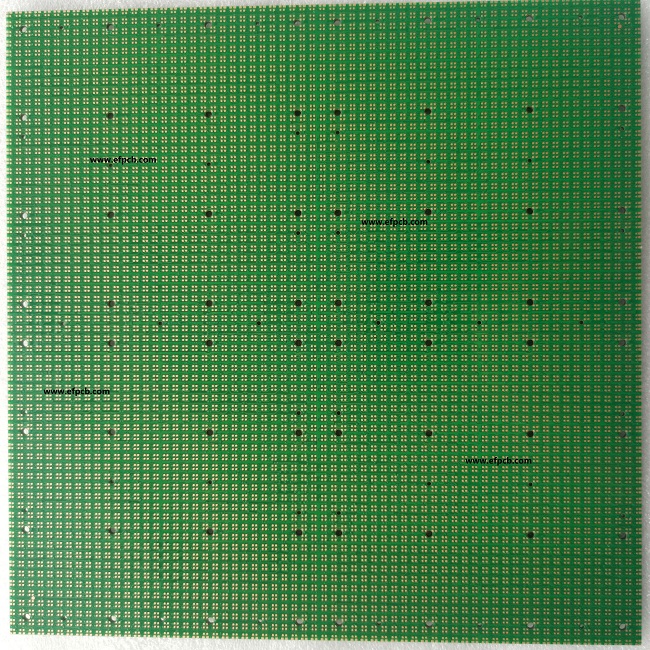

LED PCB manufacturers are the backbone of the LED lighting industry. They are the craftsmen behind the creation of Printed Circuit Boards (PCBs) that house and power the tiny but mighty LED chips. These manufacturers play a pivotal role in ensuring the reliability, efficiency, and quality of LED products.

Here's why LED PCB manufacturers are crucial:

- Precision Engineering: LED PCBs are designed with precision to accommodate various LED components, ensuring optimal electrical connections. The manufacturer's expertise in designing and assembling these boards directly impacts the LED's performance.

- Thermal Management: LEDs produce heat, and effective thermal management is essential to maintain their longevity and efficiency. Quality LED PCB manufacturers incorporate heat-dissipating materials and designs to keep LEDs cool under operation.

- Energy Efficiency: LED PCBs must be designed to maximize energy efficiency. Manufacturers can achieve this through the careful selection of materials and component placement, helping LEDs consume less power while producing light.

- Product Longevity: LED PCB manufacturers ensure that the PCBs are built to last. This durability is crucial for LED lighting products, which often have long lifespans.

- Customization: LED PCBs can be tailored to specific lighting applications. Manufacturers offer customization options to meet the unique requirements of various industries, such as automotive, residential, and commercial lighting.

Choosing the Right LED PCB Manufacturer

Selecting the right LED PCB manufacturer is critical for the success of your LED lighting project. Here are some important factors to remember:

- Expertise and Experience: Look for manufacturers with a proven track record in LED PCB production. Experience matters, as it often translates to higher quality and reliability.

- Quality Control: Check if the manufacturer has stringent quality control processes in place. Quality control ensures that every PCB leaving the factory meets the specified standards.

- Certification: Verify if the manufacturer complies with industry standards and holds relevant certifications, such as ISO 9001 and ISO 14001.

- Customization Options: Depending on your project's requirements, choose a manufacturer that can provide customized LED PCB solutions tailored to your needs.

- Technical Support: Assess the level of technical support and guidance the manufacturer offers. Effective communication can save time and reduce the likelihood of errors in the design and production phases.

- Cost and Lead Times: Consider your budget and project timeline. Compare quotes and lead times from different manufacturers to make an informed decision.

The Function of LED PCB Producers in the Market

LED PCB manufacturers are not merely suppliers; they are partners in innovation. They work hand in hand with lighting designers, engineers, and manufacturers to bring cutting-edge LED lighting solutions to life. Here is how they help the industry:

- Innovation: Manufacturers constantly push the boundaries of LED PCB technology, developing new materials, designs, and manufacturing techniques to improve LED performance and efficiency.

- Sustainability: Many LED PCB manufacturers are committed to environmentally friendly practices, using lead-free and RoHS-compliant materials in their production processes.

- Cost Efficiency: By optimizing designs and production processes, LED PCB manufacturers help reduce production costs, making LED lighting more affordable for consumers and businesses.

- Reliability: The rigorous testing and quality control procedures employed by LED PCB manufacturers contribute to the reliability and longevity of LED lighting products.

Diverse Applications of LED PCBs

The versatility of LED PCBs extends far beyond traditional lighting. LED technology has found applications in a wide range of industries, and LED PCB manufacturers are at the forefront of adapting and innovating to meet these diverse needs.

- Automotive Lighting: LED PCBs are increasingly used in automotive lighting systems, including headlights, taillights, and interior lighting. Their energy efficiency and long lifespan make them ideal for these applications. LED PCB manufacturers work closely with automotive companies to develop PCBs that meet stringent automotive standards and regulations.

- Consumer Electronics: LEDs are used in various consumer electronic devices, such as smartphones, televisions, and laptops, to indicate power status, notifications, and other functions. Miniaturized LED PCBs are designed to fit within the limited space of these devices while maintaining high performance.

- Industrial and Commercial Lighting: In industrial and commercial settings, LED PCBs are employed to create energy-efficient and long-lasting lighting solutions. LED PCB manufacturers produce robust and high-capacity PCBs that can withstand harsh environmental conditions, making them suitable for warehouses, factories, and outdoor lighting.

- Medical Devices: Medical equipment often relies on LEDs for illumination, diagnostic, and sensing purposes. LED PCBs in medical devices must meet stringent quality and safety standards, which LED PCB manufacturers are well-equipped to ensure.

- Aerospace and Defense: LED PCBs are used in aerospace and defense applications for cockpit displays, instrument panels, and exterior lighting. Manufacturers in this sector prioritize reliability, durability, and adherence to aerospace standards.

- Horticulture: LED PCBs have become indispensable in indoor horticulture for controlled and energy-efficient plant growth. Manufacturers design specialized PCBs to emit specific light spectra tailored to plant needs, optimizing growth and yield.

- Street Lighting: LED PCBs have played a significant role in the transition to energy-efficient street lighting systems worldwide. LED PCB manufacturers produce PCBs that can withstand outdoor conditions while delivering consistent and energy-saving illumination.

The Future of LED PCB Manufacturing

As technology continues to evolve, so does the LED PCB manufacturing industry. Here are some trends and innovations to look out for:

Miniaturization: As the demand for smaller and more compact devices increases, LED PCB manufacturers will continue to develop miniaturized PCBs with high performance.

Smart Lighting: The integration of LEDs with smart lighting systems is on the rise. LED PCBs will evolve to support IoT connectivity, enabling intelligent control and energy management.

Advanced Materials: Manufacturers are exploring advanced materials, such as flexible substrates and organic semiconductors, to enhance the flexibility and versatility of LED PCBs.

Sustainability: Sustainability will remain a driving force in LED PCB manufacturing. Manufacturers will increasingly adopt eco-friendly materials and processes to reduce their environmental footprint.

Conclusion

An LED PCB Manufacturer is the unsung hero behind the LED revolution. Their expertise, innovation, and commitment to quality play a vital role in ensuring that LED lighting continues to shine brightly in our lives. When embarking on an LED lighting project, choosing the right LED PCB manufacturer is a critical decision that can make the difference between an ordinary light and an extraordinary one. So, whether you're designing residential lighting or contributing to cutting-edge technology, remember that the path to LED excellence begins with the right manufacturer.