Advantages, Process Flow, and Types QFN Package

Keywords: QFN PCB assembly

The current era is witnessing the elevation in demand for integrated circuits in the automobile sector. A variety of package formats, including QFN, SOIC, and SOP are used in the automotive integrated circuits. QFN IC packages with solderable side walls are commonly utilized in automotive IC packaging. Designing QFN ICs for automotive applications differs from the standard QFN packaging production flow. You must first comprehend the conventional process flow to differentiate between the customised QFN PCB assembly package process flow and the former.

QFN stands for Quad Flat No Leads. It is distinguished by its square or rectangular form and lack of leads. A QFN package consists of bond wire, lead frame, silicon die, exposed pad, die-attach, and mould compound. The silicon die, lead frame, and solder pads are three important components. The die is the actual integrated circuit chip, which houses the IC's electrical circuitry. The lead frame connects the die to the remainder of the QFN structure, while the solder pads link the package to the circuit board, which improves thermal performance, especially for discrete devices. In this post, we'll look at QFN packages, their benefits, kinds, and process flow.

Advantages of QFN Packages

QFN packages have numerous benefits that make them ideal for a variety of electronic applications. They excel in thermal performance because of the exposed thermal pad on the bottom. Their small size and lack of leads save space, making them excellent for devices with limited space. QFN packages also have better electrical performance, with shorter electrical lines and lower inductances. They also conform to lead-free laws and are simple to handle during assembly, expediting the production process.

QFP packages are likewise square or rectangular in design, but unlike QFN packages, they contain gull-wing or J-shaped leads that extend from all four corners of the package and provide electrical connections to the circuit board. QFP packages may also accommodate more input and output pins than QFN packages due to the greater lead count. This makes QFP packages ideal for applications that require a wider range of input and output connections.

- Low cost

- Good electrical performance

- Good thermal performance and heat dissipation

- Small form factor and lightweight

- Short bond wires that join the lead frame and die

- Short bond wires result in low lead inductances.

QFN vs. QFP: Choosing the Right Package

If space on the PCB is limited and a compact size is required, QFN packages may be selected due to the lack of leads and reduced footprint. If the component requires a greater pin count and wider lead spacing, QFP packages are more suited. Thermal concerns, soldering procedures, and assembly processes all help to choose the best packaging for a given application.

QFN packages and their process flow

IC Packaging

IC packaging is vital because it protects semiconductor components within the IC from corrosion and other physical effects. Packaging serves as an insulating shell for the IC. Typically, packing materials are ceramic or plastic. IC packaging also makes it easier to attach ICs' electrical connections on printed circuit boards.

Importance of IC Packaging

IC packaging is extremely important since it incorporates the following aspects into the design:

- Functional density

- Heterogeneous integration

- Silicon scaling

- Enhanced device functionality through reduced packaging size

- Silicon yield resilience

- Faster time to market

Let's take a closer look at the various IC packaging types.

IC packages are split into two types: through-hole and surface mount. There are several types of surface mount integrated circuit packages, including:

- Small outline integrated circuits (SOIC)

- Small outline packages (SOP)

- Plastic leaded chip carriers (PLCC)

- Ball grid arrays (BGA)

- Quad flat no-lead (QFN)

QFN Packaging and Parts

A QFN package is a surface mounting technology package with no leads. The primary components of a QFN package are:

- Lead frame - The most important component of a QFN package. It determines the overall performance of the IC.

- Single or many die - The integrated circuit is made up of silicon die that are surface mounted on the PCB.

- Wire bonds are connections made of copper or gold between the lead frame and the die.

- Molding compound - Molding compound contributes to electrical insulation, corrosion resistance, and dependability in the QFN package.

Types of QFN Packages

There are several distinct types of QFN PCB assembly packaging.

QFN with tab vs QFN without tab: Some customers choose a QFN package with no thermal pad to reduce the potential of solder overflow and bridging. However, the most typical QFN packaging includes a thermal pad in the center of the device to improve heat dispersion. To avoid solder bridging, ensure that the solder paste in your exposed pad is segmented. As per the suggestion, only 40% surface of the thermal pad must be covered by the solder paste.

Air-cavity QFN: A plastic or ceramic cover, an open (without seal) molded plastic body, and a copper lead frame are present in Air-cavity QFN. Microwave systems with 20 to 25 GHz range frequency make use of Air cavity QFN packages.

Plastic molded QFNs: As compared to the air-cavity QFNs, Plastic molded QFNs exhibit less cost. They are made of a plastic composition with a copper lead frame. This QFN package is utilized in applications with frequencies ranging from 2 to 3 GHz. There is no cover on plastic molded QFN containers.

Pull-back QFN: This form of QFN package has metal pads that peel back from the edge of the component's body; the terminals are hidden once inserted.

Punch type QFN: This package is manufactured in a single mold cavity configuration, with a tool needed to separate the mold cavity.

Sawn-type QFNs: These are molded using the mold array technique, which involves cutting a large number of boxes into smaller pieces.

QFN with wettable flanks: This form of QFN allows designers to visually confirm that the pad is mounted to the PCB using the elevation supplied by the wettable flank.

Wire bond QFN - This package uses wires to link the PCB to the chip terminal.

Flip-chip QFN: A low-cost modeled package provided by flip-chip QFNs. The electrical connections in this package are made via flip-chip interconnection.

Wire bond or flip chip

Wire bonding and flip chip bonding are two assembly methods for mounting a type of QFN package with active regions or pads situated on top of the chip. The chip's terminals are directly connected to other semiconductors, integrated circuits, or PCB tracks via the wire bonding technique. For flip chip bonding, the chip is flipped downwards and immediately mounted to the board. The chip's terminals are linked to the board using solder bumps placed on the pads.

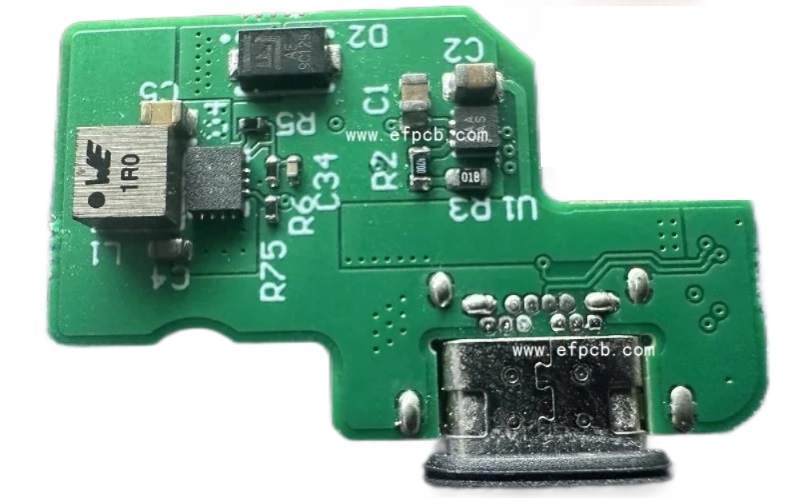

Designing QFN Packages with Different Singulations

In the QFN packaging manufacturing flow, singulation can be done using a shear or saw. Shear-singulated QFN PCB assembly packages are made individually whereas saw-singulated QFN packages are made in large batches. EFPCB can help you develop QFN IC packages for car, aerospace, and commercial applications. Leading electronics companies rely on EFPCB solutions to optimize power, space, and energy requirements across a wide range of market applications. A variety of package formats, including QFN, SOIC, and SOP are used in the automotive integrated circuits. QFN IC packages with solderable side walls are commonly utilized in automotive IC packaging.