Advantages and Applications of RF Microwave PCB

Keywords: RF Microwave PCB

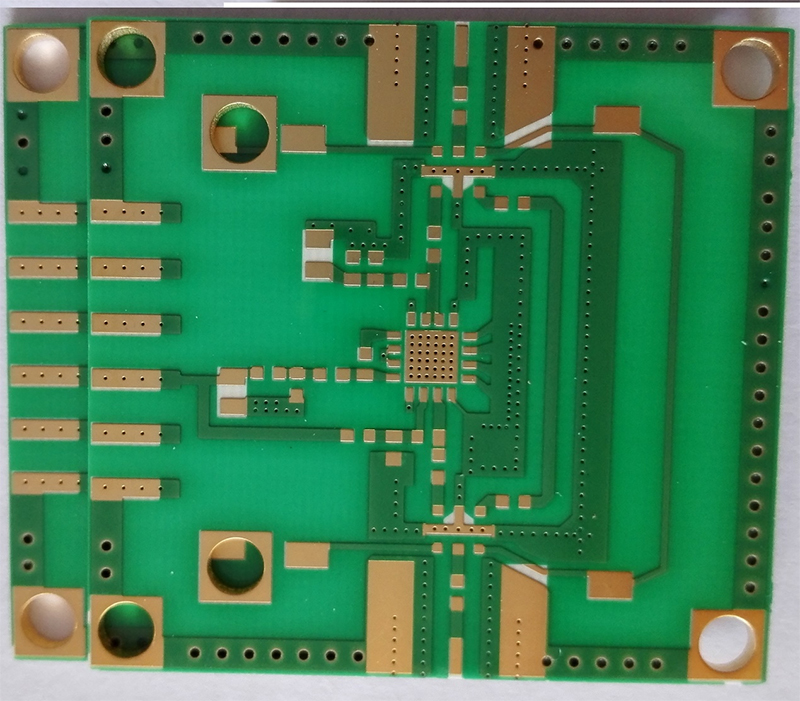

In the world of modern electronics, high-frequency applications such as wireless communications, radar systems, satellite communications, and medical imaging demand precise and efficient signal transmission. To meet these requirements, engineers and designers turn to RF (Radio Frequency) and microwave-printed circuit boards (PCBs). These specialized PCBs are designed to handle high-frequency signals with minimal loss and interference. In this blog, we will delve into the world of RF Microwave PCB and explore their advantages in today's electronics industry.

Understanding RF Microwave PCBs

RF Microwave PCBs are specially designed circuit boards that are optimized for high-frequency applications, typically ranging from hundreds of megahertz to several gigahertz. Unlike conventional PCBs, which are designed primarily for low-frequency digital or analog signals, RF Microwave PCBs are engineered to handle high-frequency signals while minimizing signal degradation, crosstalk, and other forms of interference.

Advantages of RF Microwave PCB

- Low Loss: One of the key advantages of RF Microwave PCBs is their ability to minimize signal loss. High-frequency signals are highly sensitive to transmission line losses and dielectric losses, which can significantly degrade the signal quality. RF Microwave PCBs employ specialized materials with low dielectric loss, such as PTFE (Polytetrafluoroethylene) or ceramic substrates, ensuring minimal signal loss during transmission.

- High-Frequency Capability: RF Microwave PCBs are designed to handle high-frequency signals, making them suitable for a wide range of applications. Whether it's wireless communication systems, radar systems, or satellite communication, RF Microwave PCBs offer excellent performance and reliability in transmitting and receiving high-frequency signals.

- Controlled Impedance: Impedance control is crucial in high-frequency applications, as it ensures accurate signal transmission and minimizes reflections. RF Microwave PCBs incorporate advanced manufacturing techniques, such as controlled dielectric constant and controlled trace width and spacing, to maintain precise impedance matching throughout the circuit. This results in improved signal integrity and reduced signal distortion.

- RF Shielding: RF Microwave PCB often requires shielding to minimize electromagnetic interference (EMI) and radiofrequency interference (RFI). These PCBs can be designed with specialized shielding techniques, such as grounded planes, shielded vias, or metal shielding cans, which prevent the leakage of RF signals and maintain the desired signal integrity.

- Compact and Lightweight: High-frequency devices and systems often demand compact and lightweight designs, especially in portable electronics or aerospace applications. RF Microwave PCBs allow for the miniaturization and integration of components, thanks to their high-frequency capabilities and optimized designs. This enables the development of smaller and lighter devices without compromising performance.

- Design Flexibility: RF Microwave PCBs offer a high degree of design flexibility, allowing engineers to tailor the circuit layout to meet specific requirements. The use of advanced design software and simulation tools enables the optimization of signal paths, reduction of signal loss, and minimization of crosstalk. This flexibility empowers designers to achieve better performance and faster time-to-market for their high-frequency applications.

- Thermal Management: High-frequency circuits often generate significant heat due to power dissipation. RF Microwave PCBs can be designed with effective thermal management techniques to dissipate heat efficiently. This includes the use of thermally conductive materials, heat sinks, and thermal vias to enhance heat dissipation and prevent thermal hotspots, ensuring the longevity and reliability of the circuit.

Applications of RF Microwave PCBs

The advantages of RF Microwave PCBs make them indispensable in various applications, including:

- Wireless Communications: RF Microwave PCBs are widely used in wireless communication systems, including cellular networks, Wi-Fi routers, and Bluetooth devices. These PCBs enable the efficient transmission and reception of high-frequency signals while maintaining signal integrity and minimizing interference, ensuring reliable and seamless wireless connectivity.

- Radar Systems: Radar systems rely on precise signal transmission and reception for accurate detection and imaging. RF Microwave PCBs play a critical role in radar applications by providing low-loss and controlled impedance pathways for high-frequency signals. They enable radar systems to operate with high resolution, sensitivity, and range.

- Satellite Communications: RF Microwave PCBs are vital components in satellite communication systems, enabling the transmission of signals between ground stations and satellites. These PCBs ensure efficient signal transfer, even over long distances, while minimizing losses and maintaining high data rates.

- Medical Imaging: Medical imaging technologies, such as magnetic resonance imaging (MRI) and computed tomography (CT), heavily rely on high-frequency signals for accurate and detailed imaging. RF Microwave PCBs facilitate the transmission and reception of these signals, ensuring precise imaging and diagnosis in medical applications.

- Aerospace and Defense: In aerospace and defense applications, RF Microwave PCBs are used in various systems, including avionics, radars, communication systems, and electronic warfare. These PCBs provide reliable signal transmission in challenging environments, such as high altitudes, extreme temperatures, and electromagnetic interference.

- Test and Measurement Equipment: RF Microwave PCBs are extensively used in test and measurement equipment, such as spectrum analyzers, signal generators, and network analyzers. These PCBs enable accurate measurements of high-frequency signals and ensure the integrity of test results.

Conclusion

RF Microwave PCBs have revolutionized the field of high-frequency electronics by providing efficient and reliable signal transmission. With their low loss, high-frequency capability, controlled impedance, RF shielding, and design flexibility, these PCBs offer numerous advantages in applications ranging from wireless communications and radar systems to satellite communications and medical imaging.

As technology continues to advance, the demand for RF Microwave PCBs will only increase. Engineers and designers will rely on these specialized PCBs to meet the stringent requirements of high-frequency applications while delivering optimal performance and signal integrity.

In summary, RF Microwave PCB has become indispensable in modern electronics, enabling the development of smaller, lighter, and more efficient high-frequency devices. Their ability to handle high-frequency signals with minimal loss and interference ensures the reliable operation of critical systems across various industries. As a result, RF Microwave PCBs will continue to play a vital role in shaping the future of high-frequency electronics.