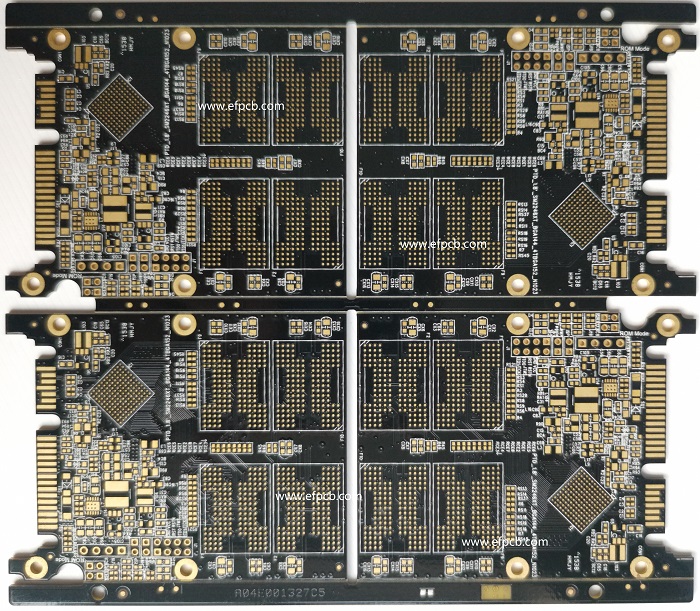

About HDI and the HDI PCB Manufacturing

Keywords; HDI PCB Manufacturing, High Volume PCB

Overview of HDI PCB Development

With the progression of universe of innovation, the need to pack more abilities into more modest bundles has likewise advanced. Utilizing HDI PCB Manufacturing strategies the planning of PCBs is done which will generally be more modest as additional parts are stuffed in a more modest space. To pack more parts into a more modest region a HDI PCB utilizes visually impaired, covered, and miniature vias, vias in cushions, and extremely meager follows.

At the point when analysts began examining ways of lessening the size of vias in PCBs, the high-density interconnect (HDI) printed circuit plan and manufacture began in 1980. In 1984 the primary creation develop or successive printed sheets showed up. Since that time, part makers generally search for ways of pressing more capabilities regardless of whether it is on a solitary chip or a solitary load up fashioners and. Today, in the IPC-2315, IPC-2226, IPC-4104, and IPC-6016 norms HDI plan and manufacture are systematized.

There are a few plan and assembling difficulties to defeat while arranging a HDI PCB plan. While planning a HDI PCB here is a short rundown of difficulties you might find:

There are bigger number of parts on the two sides of PCB stack up

Restricted board work area region

Longer follow courses makes significantly longer sign flight times

To finish the board prerequisite of more follow courses

Tighter separating and more modest parts

You can disregard the ordinary standards in High Volume PCB and make strong PCBs with exceptionally high interconnect thickness just with the right arrangement of format and steering devices based on a guidelines driven plan motor. At the point when you utilize progressed PCB plan programming that is worked for HDI PCB configuration working with high-thickness PCB steering and fine pitch parts is simple.

Distinction in HDI PCB Design and Manufacturing

From the conventional PCB producing process, the HDI fabricating process contrasts in a couple of basic yet significant ways. Significant point here is that fabricator restrictions will compel plan opportunity. It even draws the lines with regards to how the board can be steered. If you have any desire to oblige plan for assembling (DFM) necessities then it plainly shows exploiting mechanization in your plan programming. On the HDI PCB Manufacturing process the specific DFM prerequisites depend and materials used to assemble the board. At the point when we consider unwavering quality prerequisites DFM necessities additionally become significant.