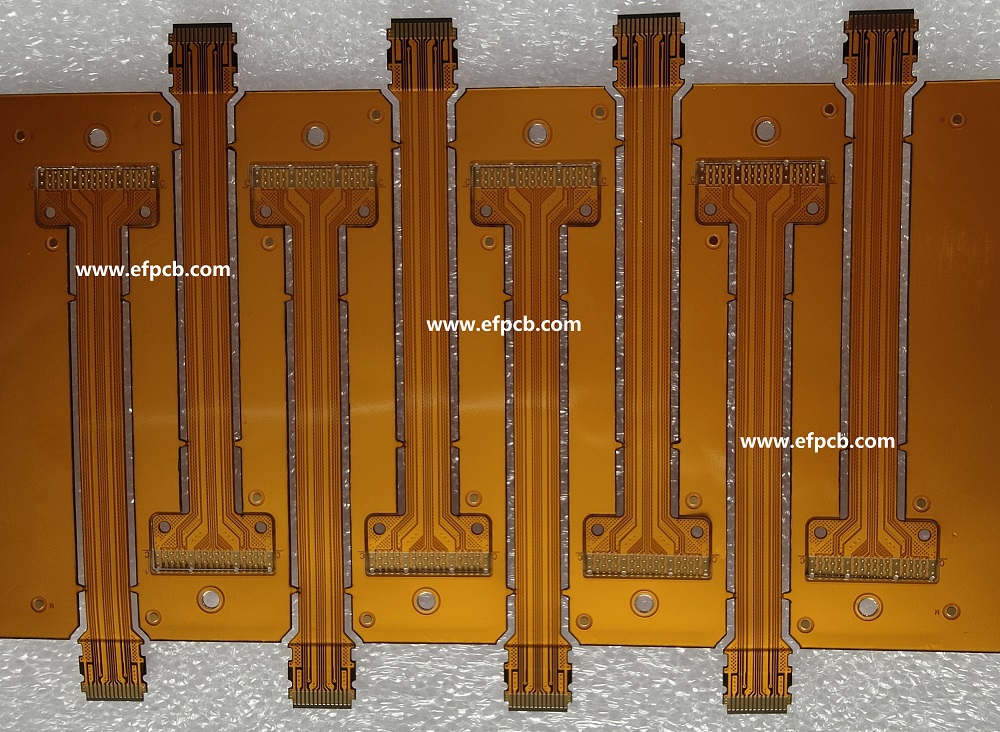

A Flexible PCBs Manufacturing Overview

Keywords: Flexible PCB, Flex Circuits Board

Flexible PCB, flex circuits, or flexible printed circuits are other names for these circuit boards. The same components used in rigid printed circuit boards are also used in the creation of these printed circuit boards.

The production of flexible PCBs

With a few significant exceptions, the production of flexible PCBs is quite similar to that of conventional rigid PCBs. Frequently, the process includes the following steps:

Design

The creation of a flexible PCB begins with the design of the board using specialist software. The bend radius, material characteristics, and component location specific to flexible PCBs must be considered in the design.

Printing

After the design is finished, it is printed utilizing a unique printing procedure onto a substrate material. Usually, a polyimide or polyester sheet that can be bent and molded into the appropriate shape serves as the substrate material.

Etching

The board is etched after printing to eliminate extra copper and produce the necessary circuits and traces. This method is comparable to the stiff Flex Circuits Board manufacturing technique.

Drilling

The board is then drilled to make holes for connections and components. The specific characteristics of the flexible material must be taken into account throughout the drilling process, as well as the requirement for precise hole placement.

Plating

A thin coating of metal, usually copper, is applied to the board after drilling to form a surface for soldering components.

Assembly

When the parts are put together on the board, it is tested for durability and functioning. The peculiarity of the flexible PCB must be taken into account throughout this procedure, along with the requirement for stable component placement.

Modern electronics find great value in flexible PCB technology, which has several advantages over rigid PCBs. Flexible PCBs are employed in a variety of applications, including mobile devices, wearable technology, medical devices, and automotive electronics, thanks to enhanced design freedom and lower production costs. Flexible PCBs are an essential component in the creation of fresh and cutting-edge goods, despite their special difficulties, such as more complexity and lower temperature tolerance. Best practices and careful planning may be used to make Flexible PCB of the highest quality that is reliable and useful for a variety of applications.

The polymeric multilayered flexible printed circuit board is made up of electrically conductive parts that are divided into more than two layers and joined by plating through holes.