Know About the Technology of PCB Fabrication

Keywords: PCB Fabrication

It's basic to fathom the principal steps engaged with making an actual PCB prior to embracing a plan for creation during PCB Manufacture. No matter what the numerous advancements accessible in every office, by far most of market-driving makers stick to a bunch of methodology to change over your plan from a computer aided design model into a genuine board.

The regular PCB Fabrication process includes a few cycles, and it is the obligation of creators to know about and understand each step. Knowing the assembling techniques makes it a lot less complex to recognize PCB plan mistakes that increment the opportunity of creation disappointments, which would require disposing of a board. Each fashioner should involve plan for assembling (DFM) methods with the goal that a PCB might be made and assembled anyplace.

A multifaceted cycle that beginnings with an item idea and finishes in a completely working PCB gathering is the printing of a printed circuit board. Along the highway, a schematic is made to address the organization network, a PCB configuration is developed, and electronic parts are bought. The circuit board will be remembered for the whole framework when the parts are fastened onto the board and after the gathering, testing, and check are done.

A few complex advances should be finished for a circuit board to find lasting success. The production of the clear board is one stage in this cycle that doesn't get the credit it merits. Because of the complex programming instruments expected for its development, the plan of a PCB draws in a ton of consideration. Assembling will get equivalent applause for making the end result. The confounding system of circuit board make, which is every now and again obscure beyond the plan local area, is in any case some place in the focal point of this.

What is the PCB fabricating process? This is the issue we will endeavor to pay all due respects to uncover the ominous starting points of a crude circuit board and the way things are ready for electrical parts to be connected to it. We will look at the stuff to construct an excellent circuit board fab that an agreement maker can rapidly collect to turn out to be truly familiar.

Standard PCB Creation Interaction

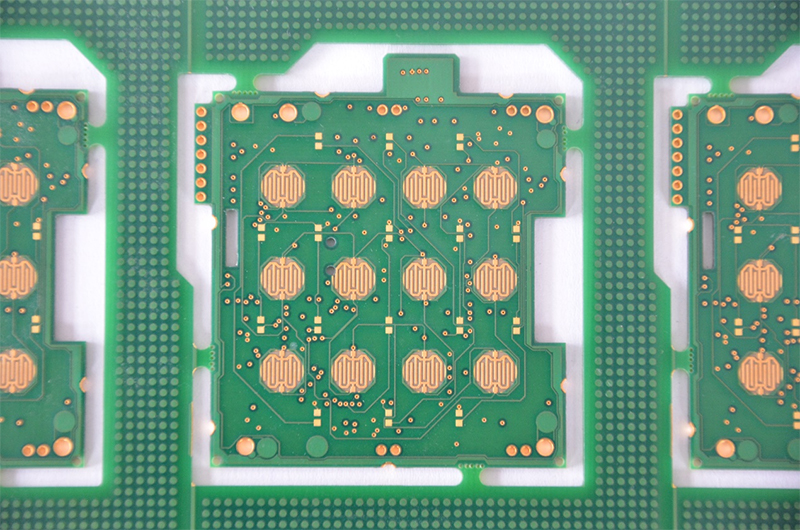

The essential strategies utilized in PCB manufacture incorporate uncovered board get together, drawing, boring, and wrapping up. The cycle stream for delivering multi-facet PCBs is displayed in the table beneath. Introductory cover materials and a total arrangement of plan prerequisites act as the beginning stage of this technique, which closes with a created board that is completely prepared for get together.

When your board is through its last relieving, a maker will begin an electrical testing strategy utilizing the test areas you determined in your PCB format. During the manufacture stage, congruity testing is many times used to check for openings and shorts between the various hubs remembered for your PCB netlist. All sheets that total this confirmation step are considered gotten done and sent into the gathering.

Various blemishes could show up during creation anytime during the PCB manufacture process. The phases of boring, plating, and scratching will frequently deliver the best imperfections.

The board could go through an extra battery of tests once the plan has passed producing and electrical testing to ensure quality. To ensure that the uncovered board creation process harms no materials or carved highlights in the PCB, this frequently involves ecological or mechanical testing.

PCB Creation Essential Prerequisites

Building the crude board that will be the reason for the completed printed circuit board gathering is known as PCB creation. A few plan viewpoints should be done before the creation seller can begin developing the crude board. Coming up next are a portion of the essentials for beginning manufacture as well as the data that the board providers will require:

Circuit Board Subtleties

The plan group will team up with their agreement maker to lay out the particulars and design of the actual board prior to beginning a PCB format. This data is expected for the plan design and for choosing the PCB fabricating supplier that is the most appropriate for the errand. A few particulars are as per the following:

• Block layer arrangement and stack

• layers of controlled impedance

• Follow essentials for width and separating

• sorts and designs of by means of

• PCB punishment worries for copper adjusting

Finished PCB Plan

The first plan should be done to ensure the accuracy of PCB manufacture. A flawed board development could emerge out of even a little part update that wasn't matched up between the schematic and the design, changing the impression. To guarantee that the plan is done and ready for assembling, you ought to initially scratch off the accompanying plan parts:

• An intensive designing assessment of the hardware was led.

• Information bases for schematics and plans are refreshed and facilitated.

• The board has been collected with all parts, and the organization associations have been steered.

• Investigations of sign respectability, power honesty, and circuit reproduction are done.

• Rules and limitations for PCB configuration are inspected, and botches are fixed.

• The BOM is analyzed for parts that are as of now being used and promptly accessible.

• For mistake free get together, plan for assembling (DFM) rules is inspected.

Full Assembling Plan Information

A complete arrangement of manufacture and gathering information documents are made and given to the agreement producer once the plan is done and ready for development. These documents will be utilized by the PCB planner for their plan assessments, after which they will send them to the creation seller at a cost on the production of the crude sheets. Remembered for these information documents are:

• Picture documents for board layers in Gerber or different arrangements

• Computer aided design models for creation and collecting

• The materials list (BOM)

• XY places of parts (pick and spot)

• Locales for test focuses

• Netlist \Schematic

The agreement producer can submit a request for the crude circuit sheets expected for the gathering after all that on the agenda has been done and is all set. The producer frequently has a rundown of prescribed fabricators to manage and will choose the provider whose abilities best match the specialized determinations of the circuit board. Whether the board being made is a model is another thought while choosing the creation supplier. Provided that this is true, the creation seller should have the option to work an alternate assembling line separated from standard strategies. To keep up with the best quality conceivable during the model development, they will likewise have to finish their plan surveys using the Gerber information.

Building the crude circuit board is the following stage subsequent to choosing the PCB Creation supplier! Uneven circuit sheets, high-thickness multi-facet plans, and flex circuits are only a couple of the few kinds of circuit sheets that might be delivered.