Get To Know All About The Rigid Flex PCB

Keywords: Rigid Flex PCB, Rigid Flexible PCB Manufacturer

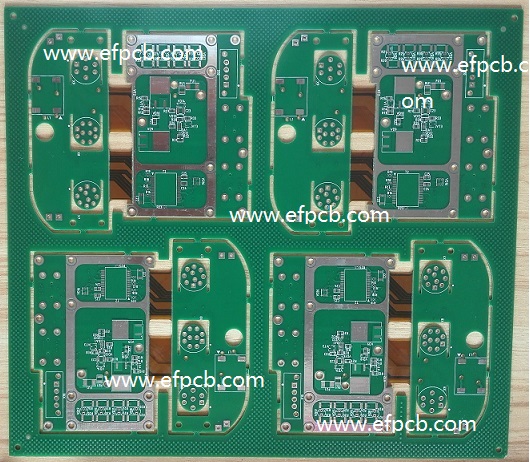

For more than 20 years there has been the use of rigid flex PCB in the military and aerospace industries. You will see that in maximum rigid-flex circuit boards, the circuitry has multiple flexible circuit inner layers that are attached with the help of an epoxy pre-preg bonding film which is quite similar to a multilayer flexible circuit.

Rigid-flex circuits constitute the best of both rigid boards and flexible circuits in one circuit. With the help of plated thru holes, the two-in-one circuit is interconnected. Rigid-flex circuits give you higher component density and better quality control.

Both rigid and flex circuits combine into a Rigid-Flex PCB board which then serves the purpose of each. They are a correct match for the medical, military, and aerospace industries because of freedom of packaging geometry, high precision, and substantial reduction of interconnects. Better quality control and higher component density are provided by these boards.

Day by day there is a tremendous increase in the demand for portable electronic circuits. Rigid Flexible PCB Manufacturer needs cost-effective solutions to blend both rigid and flex circuits into a single package.

Rigid Flex circuits provide many benefits:

Package Size and Weight Reduction –In rigid boards, more weight is created by multiple systems as a result they utilize more space. The more streamlined design is obtained by the combination of rigid boards with flexible circuits which ultimately reducing package size and weight

Lower Part Count –Combination rigid-flex circuits need fewer parts and interconnections when compared to a traditional rigid board.

Flexible Design Options –Rigid-flex circuits are designed in a way that they can meet highly complex and unimaginable configurations. Rigid-flex circuit designs may involve any of the following:

- Reduced interconnections

- Controlled Impedance

- Three to eight-layer combinations

- Highly complex configurations

High-Density Applications –For the high-density device population there is the involvement of a rigid component of a rigid-flex circuit. Along with this, flexible circuits create a way for minutely narrow lines and provide an option to the high-density device population. You can design Denser device populations and lighter conductors into a product which then frees space for additional product features.

Connection Reliability –If you want to combine Rigid Flex PCB then its base is connecting rigid layers with flexible cables.