-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

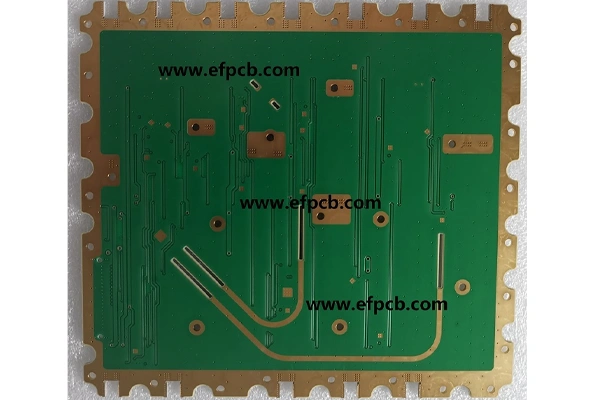

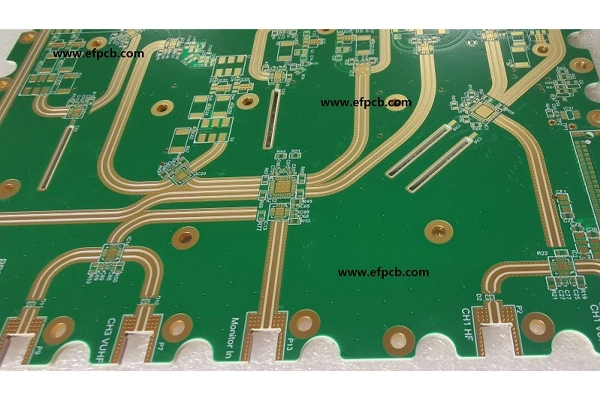

Part No.: E0414040128A

Layer count: 4

Material: R4003C ,1.6mm, , 1 OZ for all layer

Minimum tack: 8mil

Minimum space: 8mil

Minimum hole: 0.30mm

Surface finished: ENIG( Au 2 U")

Panel size: 180*163mm/1up

Characteristics: Rogers multilayer PCB, multilayer PCB, impedance control PCB

Rogers PCBs are the best choice for demanding high frequency and high performance applications due to their excellent electrical characteristics and thermal stability. These PCBs find extensive applications in telecom, aerospace, heavy machinery, automotive and medical devices where accuracy and reliability are paramount. In our capacity as foremost Rogers printed circuit boards manufacture, we are known for providing the best quality solutions specially designed for these high-end applications. We’ll cover the production of Rogers PCBs and the features and benefits of our products in this post.

Rogers PCBs utilize high-performance laminates from Rogers Corporation, which exhibit excellent dielectric properties, low loss, high thermal conductivity and are ideal for high speed or high frequency applications. Unlike traditional FR-4 based materials, Rogers materials have been specifically engineered for the highest performance at RF and microwave frequencies.

As a professional Rogers printed circuit boards producer, we utilize these high technology materials to design PCBs that satisfy the demanding requirements of HF applications. We optimize every step of our manufacturing process from the material to the testing. Rogers laminates – Features and benefits

High frequency application is achievable with the unique characteristics of the Rogers laminates, some of the important features are:

Low Dielectric Loss: This minimizes signal loss, even at high frequencies.

Consistent Dielectric Constant (Dk): Uniform performance over a broad frequency band.

Superior Thermal Conductivity: Improves heat transfer and reduces potential for thermal-related injury.

Low Thermal Expansion (CTE): Provides dimensional stability for extreme thermal cycling conditions.

High Moisture Resistance: Continues to perform in moist or adverse conditions.

Our Roger's circuit board manufacture expertise enable us to take full advantage of these materials and produce PCBs that perform in the most demanding industries.

It is important to have special Rogers PCB fabricating processes and equipment: In order to achieve the superior quality of Rogers PCB. Here are the instructions for making these high-tech PCBs.

Design and Pre-Production Planning

A comprehensive design and pre-production planning stage initiates the fabrication process. Our engineers design layouts using industry‑leading software that are tailored for high signal integrity and minimal losses. Design considerations for Rogers PCBs The consideration of the unique characteristics of the laminate should be taken into account in the design stage so that the manufactured product can be conformed to the specification.

Material selection and handling

Obtaining the right Rogers laminate is paramount to the success of a PCB. As professional Rogers PCB and Rogers PCB manufacturer, we have the most complete series of Rogers PCB materials including: RO4000, RO3000 RT ducroid series and so on to meet your special needs for different applications. The chosen material is subjected to an extensive processing.

Precision Drilling and Holes Formation

Drilling is an integral part in the production, particularly in the fabrication of multilayer Rogers PCBs. With our state-of-the-art drilling machineries, we can guarantee a superior precision for vias and holes drilling which is essential for layer to layer connectivity. We also perform laser drilling to form microvias that reduce signal loss and interference for high-frequency applications.

Circuit pattern etching

Etching is the determination of the circuit patterns on the PCB. In case of Rogers PCBs, this process has to be done with great accuracy so that the traces are remises of ferret and perfectly shaped. Irregularities in the etching pattern can be minimized by advanced chemistry etch technology, so the best effect can be performed. Multilayer Lamination

In the multilayer Rogers PCB, layers are laminated together under a certain temperature and pressure. This stage should be done with precise or the layers will not fuse together, and/or the layers will shift. Our lamination process has been designed to preserve the Rogers material properties and still achieve satisfactory bond line.

Surface Finishing

Surface finishing is essential layer for protect the PCB and PS must have the soldering for component assembling. We provide a wide range of surface finishes for applications like ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), Immersion Silver and many more.

Quality Control and Testing

All Rogers PCBs we produce undergo stringent quality control and testing to guarantee it is of superior quality. Our tests include impedance test, thermal analysis, and signal integrity verification. As a value-driven Rogers printed circuit boards manufacturer, we do not compromise on quality to deliver dependable, robust products.

Our company is known for our expertise, modern manufacturing equipment and dedication to quality. That is why you can trust us with all your Rogers PCB related requirements:

Custom Solutions: Because we know that every project has unique needs. Our team collaborates with clients to create PCBs that satisfy their unique needs.

State-of-the-Art Technology: We have the latest and most sophisticated machinery and techniques in the world to bring you precision and quality at each and every stage of the manufacturing.

Quality without Equal: We put our quality within arm distance to watch. We follow stringent quality protocols to ensure that the PCBs are consistent and can withstand adverse environmental conditions, from quality material to final testing.

Fast Turnaround Times: We know what it takes to meet a deadline. Thanks to the efficient production line we can ensure that high quality Rogers PCBs can be delivered timely without fail.

Expert Support: Our engineers and technicians offer exceptional support throughout the design and build process to make our clients’ experience with us seamless.

Rogers PCB are especially prevalent in applications where performance is critical and inherent reliability is desired. Popular applications are:

Telecommunications: Antennas, base stations, and satellite systems.

Aerospace and Defense: Radar, navigation and communication equipment.

Automotive: Advance driver- assistance systems (ADAS) and vehicle radar systems.

Medical Devices: Diagnostic imaging systems and mobile medical applications. Industrial Automation: High frequency sensors and control systems.

Since we as the Rogers PCB manufacturer have a long-time experience in this field, we have delivered trusted solutions for these industries and we are sure that you will be satisfied with our service.

Production of Rogers printed circuit boards requires expertise in technology, sophisticated tools, and a devotion to quality. We are committed to providing high quality Rogers PCBs and excellent service for the global users. If you have any questions or need any help, do not hesitate to contact us. Get in touch with us now here to find out more about how we can assist you with your next project.