-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

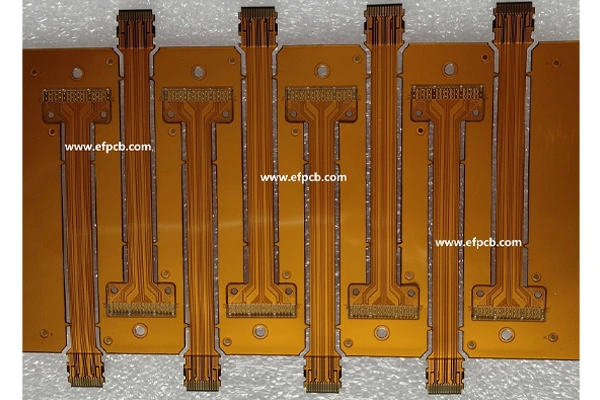

Part No.: E0475060939S

Layer count: 4 layer flex PCB

Material: Polymide, 0.30mm, 1/2 OZ

Minimum trace: 3 mil

Minimum space: 3 mil

Minimum hole: 0.25mm

Surface finished: immersion gold

Panel size: 178*107mm/8up

With electronic products getting thinner, lighter and smaller, the multilayer flex PCB technology is fast becoming the key solution for high-end interconnection. A professional multilayer flex PCB manufacturer also delivers a tightly-controlled process that ensures reliability in high density dynamic applications. Here is a brief introduction to the overall production flow, which allows you to have a glimpse of how the precision and process mastery lead to product enhancement.

A multilayer flex PCB manufacturer starts with the right materials. Polyimide films with good thermal and mechanical properties are selected as the base substrate and rolled annealed copper is widely used for outstanding flexibility and fatigue endurance. The stack-up is established at this preliminary stage to satisfy target electrical performance, bending goals, and total stack-up thickness. The next important process is imaging and etching the inner layer. Copper-clad polyimide is cleaned, photoresist-coated, and then infrared or ultraviolet (UV) exposed through high-resolution photo tools to define fine circuit patterns. After development, the unprotected copper is etched away, leaving well-defined traces and pads. An experienced multilayer flex PCB manufacturer exercises tight control over line width/ space and undercut to facilitate high-density layouts. After that inner layers are built, the buildup process starts. Several etched circuits are laminated with heat and pressure by using adhesive or by adhesiveless methods. Accuracy in registration is critical, one of the best multilayer flex PCB manufacturers will employ optical registration systems and specialized tooling to reduce layer-to-layer misregistration, and this is an extremely difficult feat to accomplish in thin, flexible materials. To form the vertical interconnections, drilling and hole formation are subsequently performed. Depending on the size of the hole and the design complexity, either mechanical drilling or laser drilling will be used. Drilling on modern multilayer flex PCB manufacturer will frequently use laser drilling for microvias and blind/buried vias. Drilling, desmear, and plasma process prepare the hole walls for further metallization (plating), resulting in vias reliability on mechanical stress (bending) as good as they can be under repeated bending. And then copper plating is performed to inexpensively deposit conductive material chemically, then reinforced through electrolytic deposit. This ensures strong inter-layer connection and reliable via integrity. A reputable multilayer flex PCB manufacturer also pays the plating thickness distribution with great attentions to provide optimal trade-off of flex, current-carrying and mechanical life. Surface protection and final definition are obtained by coverlay or flexible solder mask. The circuitry is protected by a polyimide coverlay with regulated apertures, whilst access to the pads and the stiffener sections is provided. In this case, the experience of the multilayer flex PCB manufacturer is very important because a badly designed coverlay can actually increase stress and decrease flex life. A surface finish is then deposited on the exposed pads to enhance solderability and protect the copper against oxidation. Based on customer demands, we can provide ENIG, immersion silver, OSP and other surface finishes. During this process, the quality-oriented multilayer flex PCB manufacturer will conduct in‐process inspections, electrical tests and DMAs to confirm that the impedance, thickness and bend performance are within specifications. Some high-end multilayer flex PCB fabricators may also offer pick-and-place component assembly, optical inspection, AOI, functional testing and more.

By bringing together high resolution imaging, controlled lamination, precision drilling and high strength finishing, a high quality multilayer flex PCB manufacturer can provide circuits capable of surviving dynamic flexing, small bend radii, and severe assembly procedures, making these circuits a dependable platform for advanced emerging electronic products.