-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

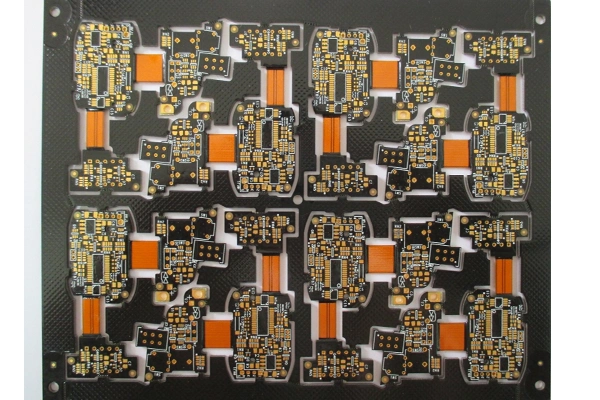

Part No.: E0415060179A

Layer count: 4 layer

Material: FR4, 1.6mm, high TG +1mil PI, 1 OZ for all layer

Minimum track: 5 mil

Minimum space: 5 mil

Minimum hole: 0.25mm

Surface finished: ENIG

Panel size: 228*328mm/8up

Rigid and flex PCBs come with both the advantages of traditional rigid PCBs and flexible PCBs, and are now a popular option for the more complex and high density designs. These PCBs are hugely popular in the aerospace domain because they are extremely reliable, use of minimum space, and have the ability to run on energy in the harsh environment for them. As a professional rigid-flexible PCB supplier, we have the capability to offer you one-stop service from designing to manufacturing, meeting your work on multiple layers high precision advanced rigid-flex products.

A rigid-flex PCB is a combination of two or more rigid PCBs connected to each other with one or more flexible layers. The rigid areas are for the strength and fixing the components, and the flexible parts are bending and folding into small space, 3D like design. This pairing makes them suitable for tools that demand both rigid and flexible features.

Manufacturing rigid-flex PCB is more complex than rigid or flex PCB, and the technology is more advanced, the process is more complicated.

Material Selection

The process involves selecting the quality raw materials among them polyimide for flex layers and FR4 for rigid parts. These materials need to be chosen thoughtfully to be compatible, durable, and perform well. As a professional rigid flex PCB manufacturer, material with high thermal and mechanical properties is our first priority to satisfy high-end applications.

Layer Stack-Up Design

The layer stack-up is a vital part of the rigid flex PCB production. The design also needs to consider the rigid flex transition term to achieve functionality and reliability. This requires exact techniques in aligning and bonding to join both portions.

Drilling and Plating

Drilling is done to make vias and holes that are eventually going to be used for electrical connections between layers. These vias are plated with copper to make them conductive. High-precision drilling and plating are critical to ensure the structural strength and the reliability of the PCB.

Lamination Process

For the bonding of the rigid and flexible layers in one lamination process, pressure and temperature must be finely regulated. The flex area still has to be flexible, and the rigid area has to be strong.

Testing and Quality Assurance

Every rigid flex PCB is tested vigorously to meet the utmost quality assurance. This includes tests for electrical continuity, bending reliability, and mechanical strength.

We are a high precision rigid flexible PCB supplier in China, and rigid flexible PCB fabrication is our core business. As the trusted rigid flex PCB manufacturer, High Quality PCB combines advanced technology, precision engineering, and quality assurance. Our experienced staff collaborates with customers to design and build unique products that fit their needs. With our high-level technology and advanced machines, we are able to make sure our rigid flexible PCBs have high quality and high reliability.

Rigid flexible PCBs consist of an integral part of modern electronic gadgets allowing innovative design and dependable functionality. The importance of having a good rigid-flexible PCB supplier to partner with cannot be overstated. Our rigid flex PCB Manufacturer have more than 15 years experience in rigid flex PCB procurement and supply and were very professional in lead time and customer services. With advanced manufacturing equipment, premium material and excellent customer services, we are the best choice of your Rigid-Flexible PCB supplier, if you have any needs just contact us.