-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

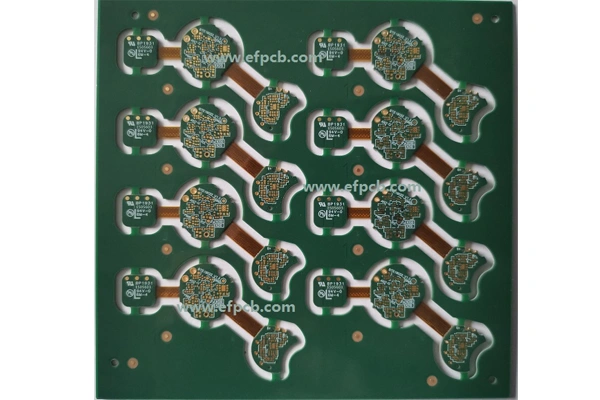

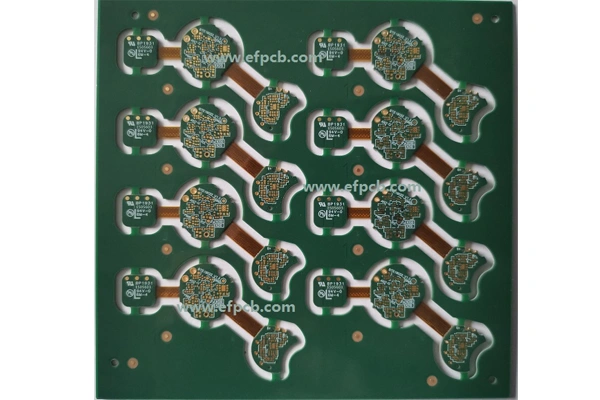

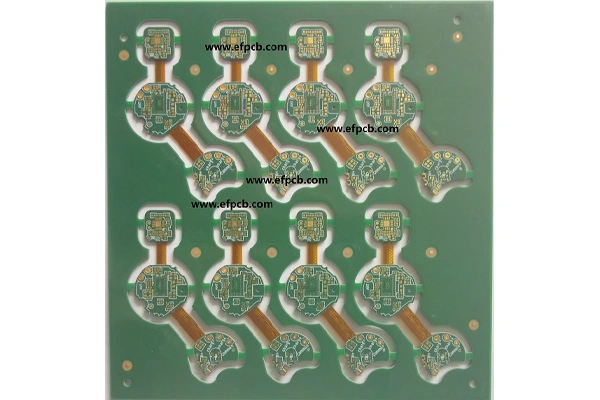

Layer count: 4

Material: FR4 + Polymide,1.6mm, 1 OZ for all layer

Minimum track: 3mil

Minimum space(gap): 3mil

Minimum hole: 0.30mm

Surface finished: ENIG( Au 2 U")

Panel size:220*230mm/8up

Production earphone rigid flex PCB production is a high tech industry that requires knowledge of advanced technology how to prove rigid flex circuits on time. As the foundation for dense and high-quality earphones, these PCBs are a must-have to support light weight designs, seamless connectivity and dependable performance. As a professional manufacturer of earphone rigid flex PCB, we pay attention to the quality of the solution the highest level of quality, durability and efficiency. This article we will to introduce the process of manufacturing earphone rigid flex PCB and the features of our products.

Earphone rigid flex PCBs are a special circuit board that includes both rigid and flex circuits. It is this unconventional formation that enables to be housed within the small curved shape of earphone. These PCBs are indispensable to provide efficient signal transmission, strong mechanical protection and space-saving design, which makes them the best options for wireless earbuds, in-ear monitors, and noise-canceling headphones.

As a reliable earphone rigid flex PCB manufacturer, we are good at developing PCBs that perform well in miniature audio devices. Our products are professional designed for earphone and the quality is reliable and sound is very good.

Rigid flex earphone PCBs production is a precise and tightly monitored process composed of multiple steps. All the steps are important to ensure a high quality end product that can hold up to the demanding requirements of high end earphones.

Material Selection and Preparation

The manufacturing is customized with high quality raw materials in line with the earphone design. The rigid planes and core are normally composed of high-grade FR4, while the flexible substrates are polyimide. These material should have good thermal stability, mechanical properties and electrical properties.

We are a professional earphone rigid flex PCB supplier; high quality materials are used in our production to guarantee good reliability and performance. In selecting materials for our processes, we follow the specific needs of compact earphone designs, including the ability to produce PCBs with tightly packed components that are still easy to assemble.

Circuit Patterning

Circuit patterning means forming circuit on the PCBs. The first photolithographic steps are the depositing of the photoresist layer, exposing the layer to light through a mask and developing the layer to remove the exposed or non-exposed areas, followed by etching the unnecessary copper to create the desired circuit patterns. For earphone, the pattern of the circuit electrodes should be small and accurate to be contained inside an enclosure of a small size. Employ laser imaging and fine line etch processes to manufacture high quality, complex circuit patterns with great precision. We guarantee that our earphone rigid flex PCB can satisfy the HDI requirements of your up-to-date audio equipment.

Drilling and Via Formation for Rigid Flex PCB

Vias are small holes drilled through the PCB, or printed circuit board that connect different layers of the PCB. They are plated with copper then it becomes easy reliable electrical conductivity. For earphone designs, the vias have to be small and perfectly aligned so that the compact size of the PCB is kept.

As an earphone rigid flex PCB manufacturer, we are able to implement sophisticated via technologies such as microvias & blind vias. These solutions provide increased interconnect density and electrical performance to meet the tight space requirements of tiny earphone designs.

Lamination and Layer Bonding

The rigid and flexible portions of the PCB stack up, when printed circuit boards are made using a rigid-flex or flexible PCB lamination process, the rigid and flexible sections of a PCB stack up are laminated together under controlled pressure and temperature conditions. This creates strong bonding between the layers and increases mechanical integrity of the PCB. Lamination of an earphone has to have the right tradeoff in flexibility and rigidity. Our lamination process is controlled for stress and uniformity so that the resulting PCBs have good structural integrity and low warpage. This makes for a dependable, durable product in the harsh conditions of daily use in earphones.

Application of Surface Finishing and Solder Mask of Rigid Flex PCB

Surface finishing is used to cover and protect the bare copper traces and also makes the whole PCB easier for soldering. Popular finishes for hard disk drives are electroless nickel immersion gold (ENIG) and organic solderability preservatives (OSP). A solder mask is then added to cover the entire PCB, which insulates it and helps to avoid short circuits when the PCB is assembled.

We provide various surface finishes depending on the type of earphone rigid flex PCB. Our advanced process gives superior solderability, excellent corrosion resistance, and proven long-term reliability for your high-end audio products.

Testing and quality control

Quality testing is a rigorous part of our earphone rigid flex PCBs manufacture process and with testing method at the end of manufacture. It includes electrical test, dimension check and reliability test to verify the PCB is within the specification.

Being a reliable earphone rigid flex PCB supplier, we utilize sophisticated testing machinery such as automated optical inspection (AOI) and x-ray to identify defects and to ascertain the consistency of quality. Each PCB is tested in the full application for the best performance.

Proprietary Mobility of Our Earphone Rigid Flex PCB The noise cancellation is well known convenient feature for non-stop music lover.

Our earphone rigid flex PCBs are tailored to our clients challenging modern audio device solutions. Here are a few key characteristic that makes our products special:

üCompact and Lightweight Design: Our PCBs are developed to be packaged along with the small form factor of earphones, allowing the creation of lightweight and comfortable designs.

Extreme Flexibility and Strength: Our rigid-flex PCB is strong and reliable due to high extension capabilities of flex layers, which can be bent or twisted numerous times without breaking.

Outstanding Signal Integrity: High-quality materials and precise manufacturing technology effectively reduce signal loss and interference, providing high-quality sound.

Tailored Solutions: We partner with customers to create custom designed PCBs that meet specific requirements and desired performance.

Green Manufacturing: We live by sustainability. We employ green processes and materials to minimize our environmental impact.

To sum up, production of earphone rigid flex PCB is a highly specialized and complicated process which demands leading edge technologies, precision engineering and dedication to quality. With our reliable and flexible experiences in the field of earphone rigid flex PCB, we are able to provide the best quality product and service to customers. The earphone rigid flex PCB we provide is made in accordance with industry quality standards, which ensures it is compact in size and easy to handle. Customers who work with us have access to top-notch PCBs that empower innovation and enhance the audio experience for users all over the world. The demands of today's audio devices are met by our earphone rigid flex PCBs. They have the right flexibility, durability, and electrical capabilities to make possible designing small, high-quality sound devices.