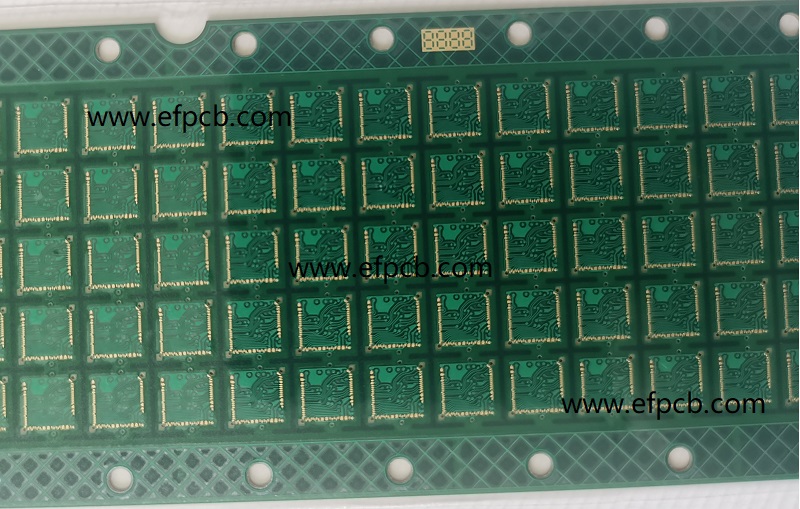

Know About the Multi-Layer IC Substrate Design in PCBs

Keywords: IC Substrate PCB

In the fast-paced realm of electronic engineering, the demand for smaller, faster, and more efficient devices has driven innovations in Integrated Circuit (IC) design. At the heart of these advancements lies the intricate world of Multi-Layer IC Substrate Design within IC Substrate PCB. This article aims to demystify the complexities of this design approach, shedding light on its significance in the ever-evolving landscape of electronic devices.

IC Substrate Design

IC substrate, often referred to as the PCB, serves as the foundation for electronic components and interconnections in a device. It plays a crucial role in providing mechanical support, electrical connectivity, and thermal management. Traditional single-layer PCBs are now making way for multi-layer designs, offering improved performance, compactness, and enhanced functionality.

Benefits of Multi-Layer IC Substrate Design

Enhanced Signal Integrity

Multi-layer PCBs allow for the efficient routing of signals in different layers, minimizing signal interference and maintaining signal integrity. This is particularly crucial in high-frequency applications where signal clarity is paramount.

Reduced Electromagnetic Interference (EMI)

By distributing components across multiple layers, EMI can be mitigated. This is achieved through careful placement and routing, reducing the likelihood of electromagnetic interference that can degrade the overall performance of the device.

Compact Form Factor

Multi-layer designs enable a higher component density within a smaller footprint. This is essential for modern devices where space constraints are a critical consideration. Compact form factors are particularly beneficial in consumer electronics, wearables, and IoT devices.

Improved Power Distribution

The power delivery network in multi-layer designs can be optimized to ensure efficient and stable power distribution throughout the PCB. This is vital for preventing voltage drops and ensuring that each component receives the necessary power for optimal performance.

Thermal Management

Efficient dissipation of heat is a significant concern in electronic devices. Multi-layer IC Substrate PCB facilitate the integration of thermal vias and planes, enhancing the board's ability to dissipate heat effectively. This is particularly important in high-power applications such as microprocessors and GPUs.

Key Considerations in Multi-Layer IC Substrate Design

Layer Stackup

The arrangement and ordering of layers, known as the stackup, play a pivotal role in the performance of the multi-layer PCB. Proper layer stackup ensures optimal signal integrity, controlled impedance, and effective heat dissipation. Engineers must carefully consider factors such as signal frequency, power distribution, and thermal management when determining the layer stackup.

Signal Integrity and Controlled Impedance

Maintaining signal integrity and controlled impedance are critical aspects of multi-layer IC substrate design. High-speed signals can experience degradation due to impedance mismatches, reflections, and crosstalk. Designers must use specialized tools and techniques to ensure that these issues are mitigated, such as employing differential pairs, impedance-controlled traces, and proper termination techniques.

Power Delivery Network

The power delivery network includes the distribution of power and ground planes. Proper design of power planes and their connection to components is essential for stable power distribution. Decoupling capacitors are strategically placed to suppress voltage fluctuations and noise, ensuring that each component operates within its specified voltage range.

Thermal Considerations

Thermal management is a crucial consideration in multi-layer IC substrate design. The inclusion of thermal vias and planes helps dissipate heat effectively, preventing overheating and ensuring the longevity of electronic components. Engineers employ simulations and analysis tools to optimize the placement of thermal features.

Component Placement and Routing

The placement of components and the routing of traces demand meticulous attention in multi-layer designs. Critical components must be strategically located to minimize signal travel distances and optimize thermal pathways. Automated routing tools aid in efficiently creating trace routes while adhering to design constraints.

Challenges in Multi-Layer IC Substrate Design

Complexity and Cost

The increased complexity of multi-layer designs can translate to higher manufacturing costs. The fabrication and assembly processes become more intricate, requiring advanced technologies and precision. Balancing cost considerations with the benefits of enhanced performance poses a challenge for designers.

Signal Integrity Issues

Despite advancements in design tools, signal integrity issues can still arise in multi-layer PCBs. Addressing challenges such as crosstalk, reflections, and impedance matching requires a deep understanding of high-frequency behavior and sophisticated simulation tools.

Thermal Management

While multi-layer designs offer improved thermal management, challenges persist in dissipating heat efficiently, especially in devices with high power densities. Designers must strike a balance between component placement, thermal features, and the overall form factor of the device.

The choice of substrate materials is a critical factor in multi-layer IC design. Emerging materials with enhanced thermal conductivity, flexibility, and electrical performance are being explored.

Real-world Applications

5G Communication Systems

The rollout of 5G communication networks relies heavily on the capabilities of multi-layer IC substrates. These substrates enable the high-frequency transmission of signals required for the increased data rates and low-latency communication that 5G promises. Advanced signal integrity and efficient thermal management are crucial in the design of 5G infrastructure components.

High-Performance Computing (HPC)

In the realm of HPC, where processing power is a critical factor, multi-layer IC substrates play a pivotal role. The integration of multiple processors, memory modules, and high-speed interconnects demands a carefully designed substrate to ensure optimal performance and thermal efficiency. HPC applications benefit from the compact form factors enabled by multi-layer designs.

Wearable and IoT Devices

The trend toward smaller, more feature-rich wearable devices and IoT gadgets is made possible by advancements in multi-layer IC substrate design. These substrates allow for the integration of sensors, communication modules, and processing units in compact form factors. The efficient use of space and power is paramount in these applications.

Conclusion

Multi-layer IC Substrate PCB design in PCBs represents a paradigm shift in the field of electronic engineering. As devices continue to evolve and demand higher performance, the advantages offered by multi-layer designs become increasingly essential. Engineers and designers must navigate the complexities of layer stackup, signal integrity, power delivery, and thermal management to create robust and efficient electronic systems. Despite the challenges, the benefits of enhanced signal integrity, reduced EMI, compact form factors, improved power distribution, and efficient thermal management make multi-layer IC substrate design a cornerstone of modern electronic devices. As technology advances, so too will the intricacies of PCB design, pushing the boundaries of innovation and enabling the development of more powerful, compact, and reliable electronic devices.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact