Know About the Flexible PCB Assembly Techniques

Keywords: Flexible PCB Manufacturer

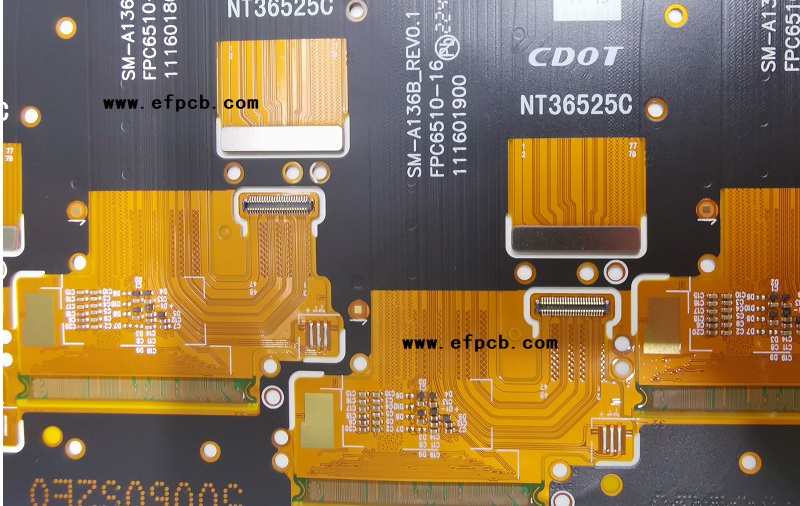

In the dynamic landscape of electronic devices, flexibility has become a key factor driving innovation. Traditional rigid printed circuit boards (PCBs) are giving way to their more adaptable counterparts, flexible PCBs from Flexible PCB Manufacturer. These flexible circuits open up a realm of possibilities for design engineers, allowing for the creation of lightweight, bendable, and even wearable electronic devices. In this blog, we will delve into the exciting world of Flexible PCB Assembly Techniques, exploring the methods that make these marvels of technology possible.

Flexible PCBs

Flexible PCBs, also known as flex circuits or flex boards, are made from flexible materials that allow them to conform to different shapes and contours. Unlike rigid PCBs, which use hard substrates like fiberglass, flexible PCBs use flexible polymer materials such as polyimide. These materials provide the necessary durability and flexibility for the circuit to bend and twist without compromising functionality.

Key Advantages of Flexible PCBs:

Space Efficiency

Flexible PCBs excel in applications where space is at a premium. Their ability to bend and fold allows for more efficient use of available space, enabling the creation of compact and sleek electronic devices.

Weight Reduction

Traditional PCBs can be heavy and cumbersome. Flexible PCBs, being lighter and thinner, contribute to overall weight reduction in electronic devices, making them more portable and user-friendly.

Enhanced Reliability

The absence of solder joints and connectors, common points of failure in rigid PCBs, contributes to the increased reliability of flexible PCBs. The flexibility of the substrate also reduces the risk of mechanical failure due to stress or vibration.

Cost-Effective Manufacturing

The manufacturing process for flexible PCBs is often more cost-effective than that of rigid PCBs. Their streamlined production, reduced material usage, and simplified assembly contribute to lower overall costs.

Flexible PCB Assembly Techniques

Surface Mount Technology (SMT)

SMT is a widely adopted assembly technique for both rigid and flexible PCBs. It involves placing and soldering surface-mounted components directly onto the PCB's surface. The compatibility of flexible substrates with SMT makes it a preferred method for assembling flexible circuits.

Additive Manufacturing

Additive manufacturing, or 3D printing, has entered the realm of flexible PCB assembly. This technique allows for the creation of complex and customized designs, offering flexibility in circuit layout. Conductive inks and materials compatible with flexible substrates are used in the 3D printing process.

Adhesive Bonding

Adhesive bonding is a technique where components are attached to the flexible substrate using adhesives. This method is advantageous for creating lightweight and flexible electronic assemblies. Advanced adhesives ensure strong bonds while maintaining the flexibility of the PCB from Flexible PCB Manufacturer.

Roll-to-Roll Manufacturing

Roll-to-roll manufacturing is a continuous and automated assembly process that is well-suited for flexible PCBs. This technique involves feeding a flexible substrate through a series of processing stations, allowing for high-volume production with increased efficiency.

Embedding Components

In this technique, components are embedded within the flexible substrate, providing a more streamlined and compact design. Embedding components reduces the overall footprint of the device and enhances its resistance to environmental factors.

Applications of Flexible PCBs

Wearable Electronics

Flexible PCBs are a cornerstone in the development of wearable devices. From smartwatches to fitness trackers, the ability to bend and conform to the body's contours is essential for the comfort and functionality of these devices.

Medical Devices

In the medical field, flexible PCBs find applications in devices such as medical sensors, diagnostic equipment, and implantable devices. The flexibility of these circuits allows for seamless integration into various medical applications.

Automotive Electronics

The automotive industry benefits from flexible PCBs in applications like in-vehicle infotainment systems, sensors, and control modules. The ability to conform to the shape of the vehicle's interior enhances design flexibility.

Consumer Electronics

Flexible PCBs are increasingly used in consumer electronics, including smartphones, tablets, and cameras. The lightweight and space-efficient nature of flexible circuits contributes to the development of slimmer and more portable devices.

Challenges and Considerations in Flexible PCB Assembly

Material Compatibility

Choosing the right materials is crucial in flexible PCB assembly. Not all components and materials are compatible with flexible substrates, and designers must carefully consider the thermal and mechanical properties of the chosen materials to ensure reliability.

Bending Radius

While the flexibility of these circuits is a significant advantage, it is essential to consider the bending radius limitations. Excessive bending can lead to material fatigue and compromise the integrity of the circuit. Designers must carefully determine the acceptable bending radius for the specific application.

Surface Finish

The choice of surface finish on flexible PCBs is critical for ensuring proper soldering and overall reliability. Common surface finishes include gold, nickel, and immersion silver. The selection depends on the specific requirements of the application and the compatibility with flexible substrates.

Testing Challenges

Traditional testing methods used for rigid PCBs may not be directly applicable to flexible circuits due to their unique characteristics. Specialized testing techniques are required to ensure the functionality and reliability of flexible PCBs. Designers need to account for these differences during the testing phase of production.

As technology continues to evolve, so too will the capabilities of flexible PCBs. The ongoing research and development in materials, manufacturing processes, and integration techniques are poised to bring about even more advanced and groundbreaking applications. The challenges associated with flexible PCB assembly, such as material compatibility and testing methods are actively being addressed, driving the industry toward greater reliability and efficiency.

Conclusion

Flexible PCB assembly techniques by Flexible PCB Manufacturer have revolutionized the way electronic devices are designed and manufactured. The ability to create lightweight, bendable, and adaptable circuits opens up new possibilities for innovation across various industries. As technology continues to advance, flexible PCBs will play an increasingly integral role in shaping the future of electronic devices, providing a foundation for the development of smarter, more compact, and user-friendly products. For design engineers, these flexible circuits provide a world of possibilities, enabling the development of thin, flexible, and even wearable electronic systems.