Are You Aware of the Benefits of Gold Finger PCBs?

Keywords: Gold Finger PCB Manufacturer

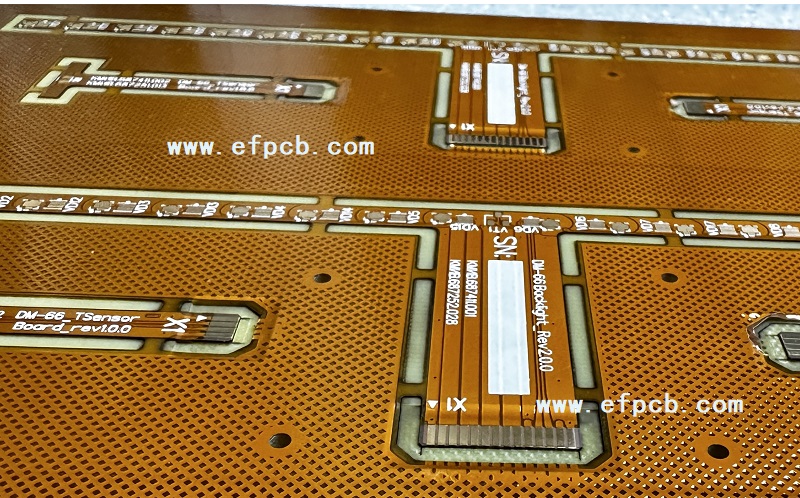

Printed Circuit Boards (PCBs) are the backbone of electronic devices, facilitating the seamless flow of electrical signals between components. Gold Finger PCBs have emerged as a technological marvel, revolutionizing the way electronic devices are designed and manufactured. Gold Finger PCBs, characterized by their gold-plated connectors along the edges, offer a plethora of advantages that contribute to their widespread adoption in various industries. In this blog, we will explore the numerous benefits of Gold Finger PCBs from Gold Finger PCB Manufacturer, shedding light on why these specialized circuit boards are the gold standard in electronic design.

Exceptional Conductivity

Gold Finger PCBs owe their name to the gold plating on their connectors, and this gold layer plays a pivotal role in enhancing conductivity. Gold is an excellent conductor of electricity and does not corrode, ensuring a reliable and stable connection over time. This exceptional conductivity is particularly crucial in high-frequency applications and devices where signal integrity is paramount. Gold Finger PCBs are favored in industries such as telecommunications, aerospace, and medical devices, where precision and reliability are non-negotiable.

Corrosion Resistance

Gold is resistant to corrosion and oxidation. This inherent property of gold ensures that Gold Finger PCBs maintain their structural integrity and electrical performance over an extended period. In environments with high humidity, varying temperatures, or exposure to corrosive elements, the gold plating acts as a protective layer, prevents the connectors from degrading. This corrosion resistance contributes significantly to the longevity and reliability of electronic devices, making Gold Finger PCBs a preferred choice for mission-critical applications.

Enhanced Aesthetics and Brand Image

Beyond their technical prowess, Gold Finger PCBs also offer aesthetic benefits. The distinctive gold plating not only adds a touch of elegance to electronic devices but also signifies a commitment to quality and precision. This visual appeal can be especially crucial in consumer electronics, where the appearance of a product can influence purchasing decisions. The use of Gold Finger PCBs can enhance the overall brand image, signaling to consumers that the manufacturer prioritizes performance and durability in their products.

Improved Solderability

Soldering is a critical step in the assembly of electronic devices, and the choice of PCB material can significantly impact the soldering process. Gold Finger PCBs from Gold Finger PCB Manufacturer, with their gold-plated surfaces, exhibit excellent solderability. The gold layer creates a smooth and uniform surface that promotes strong and reliable solder joints. This characteristic is particularly advantageous during the manufacturing phase, as it reduces the likelihood of defects and ensures a more efficient production process. The improved solderability of Gold Finger PCBs contributes to overall manufacturing cost-effectiveness and product quality.

High-Temperature Stability

Electronic devices often operate in demanding environments characterized by high temperatures. Gold Finger PCBs excel in such conditions due to the high-temperature stability of gold. The metal retains its properties even at elevated temperatures, ensuring that the connectors remain intact and functional. This thermal stability is crucial in applications such as automotive electronics and industrial equipment, where components are exposed to extreme temperatures during operation. Gold Finger PCBs provide a reliable solution for electronic systems that must withstand challenging thermal environments.

Excellent Wear Resistance

In applications where connectors are frequently plugged and unplugged, wear resistance is a critical consideration. The gold plating on Gold Finger PCBs exhibits excellent wear resistance, ensuring that the connectors maintain their performance even after numerous insertion cycles. This durability is particularly valuable in devices such as smartphones, tablets, and other portable electronics, where connectors are subjected to constant use. Gold Finger PCBs contribute to the longevity of electronic devices by withstanding the wear and tear associated with regular usage.

Facilitates High-Density Designs

The compact and high-density nature of electronic devices demands PCBs that can accommodate intricate designs without compromising performance. Gold Finger PCBs, with their superior conductivity and precision manufacturing processes, are well-suited for high-density designs. The gold-plated connectors allow for fine pitch designs and reliable signal transmission in densely populated circuits. This characteristic makes Gold Finger PCBs an ideal choice for applications where miniaturization is a priority, such as in medical implants, wearable devices, and other compact electronics.

Environmental Sustainability

Beyond their technical advantages, Gold Finger PCBs contribute to environmental sustainability. Gold is a highly recyclable material, and the recycling process doesn't compromise its quality. As electronic waste becomes a growing concern, the recyclability of Gold Finger PCBs helps reduce the environmental impact of discarded electronic devices. Manufacturers and consumers alike are recognizing the importance of sustainable practices, and the use of recyclable materials like gold in PCBs aligns with these eco-friendly initiatives.

Electrochemical Stability

Gold's electrochemical stability is a crucial factor in the performance of Gold Finger PCBs. In environments where chemical reactions are prevalent, such as those involving harsh cleaning agents or exposure to certain gases, the electrochemical stability of gold prevents degradation. This stability ensures that the connectors maintain their performance characteristics, making Gold Finger PCBs suitable for applications where chemical resistance is imperative, such as in laboratories and industrial settings.

Low Contact Resistance

The gold plating on the connectors of Gold Finger PCBs contributes to low contact resistance. Low contact resistance is essential for maintaining the efficiency of electrical connections and minimizing power losses. This characteristic is particularly advantageous in high-current applications where even minor resistive losses can result in significant heat generation. By ensuring low contact resistance, Gold Finger PCBs enhance the overall energy efficiency of electronic devices, making them an ideal choice for power-sensitive applications.

Reliability in Harsh Environments

Gold Finger PCBs demonstrate remarkable resilience in harsh environments. The combination of gold's physical durability and the PCB's robust construction ensures that the connectors withstand the challenges posed by these conditions. Gold Finger PCBs are sought after in applications where reliability under adverse conditions is non-negotiable.

Market Acceptance and Industry Standards

The widespread acceptance of Gold Finger PCBs in various industries is reflected in industry standards and specifications. Many electronic device manufacturers adhere to standards that recommend or require the use of gold-plated connectors in specific applications. This acceptance is a testament to the proven performance and reliability of Gold Finger PCBs. Manufacturers, engineers, and designers often prioritize components that align with established industry standards, further cementing the position of Gold Finger PCBs in the market.

Conclusion

In conclusion, Gold Finger PCBs from Gold Finger PCB Manufacturer stand as a testament to the relentless pursuit of excellence in electronic design and manufacturing. Their exceptional conductivity, corrosion resistance, aesthetic appeal, solderability, high-temperature stability, wear resistance, and ability to facilitate high-density designs make them a preferred choice across various industries. As electronic devices continue to evolve, the demand for reliable and high-performance components like Gold Finger PCBs is expected to rise.